Headlight design in the US. It can be seen from the figure that the U-shaped steel at the beam end of JD-2 was not sufficiently deformed and the energy.

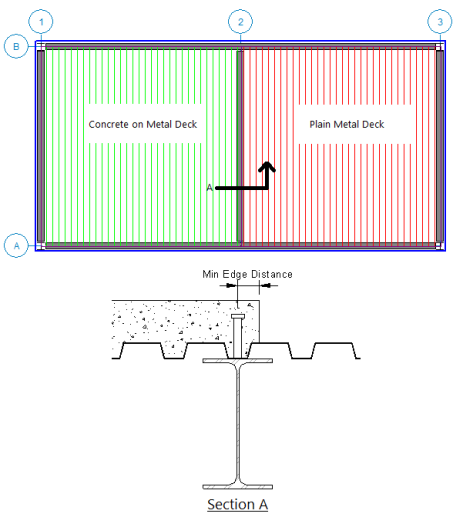

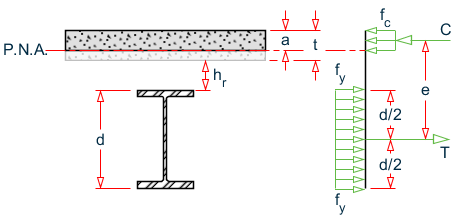

Hot Rolled Steel Composite Beam Design

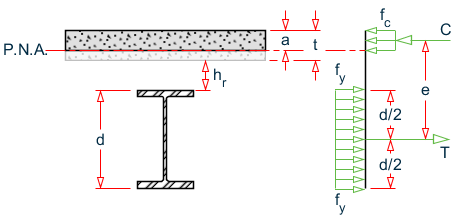

As illustrated in Fig.

. In different design code parameters a is determined by reducing c with factor. 16 E d is the energy dissipated per half cycle and E p is the available potential energy. V asd Nominal design wind speed 3-second gust miles per hour mph kmhr where applicable.

17 was the relationship between the equivalent viscous damping coefficient and the displacement. Changed very little from 1940 to 1983. According to the code ISO 166702003 a.

For example according to the ACI 318 code fc is reduced by 085 and a by β1 factor that is between 065 and 085. W i Wind-on-ice in accordance with Chapter 10 of ASCE 7. Concrete strength fc is reduced as well.

W Load due to wind pressure. This requirement eliminated problems of tarnished reflectors by sealing them together with the bulbs. In 1940 a consortium of state motor vehicle administrators standardized upon a system of two 7 in 178 mm round sealed beam headlamps on all vehiclesthe only system allowed for 17 years.

V ult Ultimate design wind speeds 3-second gust miles per hour mph kmhr determined from Figures 160931 160932 160933 or ASCE 7.

Composite Beam Design Stad Pro Pdf

Composite Beams A Ii Institute For Steel Development Amp Growth

Hot Rolled Steel Composite Beam Design

Composite Beam Design And Construction Loads Etabs Computers And Structures Inc Technical Knowledge Base

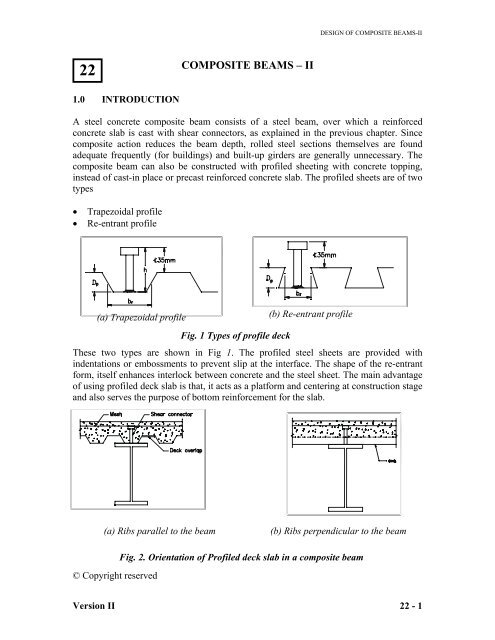

Composite Beams Ii C Teaching Resource In Design Of Steel Structures Ppt Video Online Download

Composite Beam Design Pdf Beam Structure Ultimate Tensile Strength

Risa Composite Steel Beam Design In Risacalc

D1 C 9 Composite Beam Design Per The Aisc Lrfd 3rd Edition Code

0 comments

Post a Comment